Suspension parts

MIVO is one of the leading custom suspension parts manufacturers for commercial vehicles and aftermarket upgrades.

- Custom Solutions: MIVO has designed suspension components for various vehicle applications, including types of light-duty and medium-duty/heavy trucks.

- High-Quality Standards: MIVO guarantees high-quality suspension parts with every purchase, based on TS16949 and ISO 9001 certifications.

- Fast Delivery: MIVO provides to arrive on schedule and finish most projects within 45-60 days to keep your project under control.

- Competitive Pricing: MIVO offers factory-direct pricing, which eliminates middlemen to provide cost-effective solutions.

Suspension component manufacturing expert

Your one-stop suspension parts manufacturer

-

Control Arms

For SUVs and pickup trucks in challenging driving conditions, our forged steel control arms offer accurate alignment and long-lasting strength.

-

Ball Joints

Our powder-metallurgy suspension ball joints are ideal for OEM replacements and aftermarket modifications because they offer smoother steering and longer wear life.

-

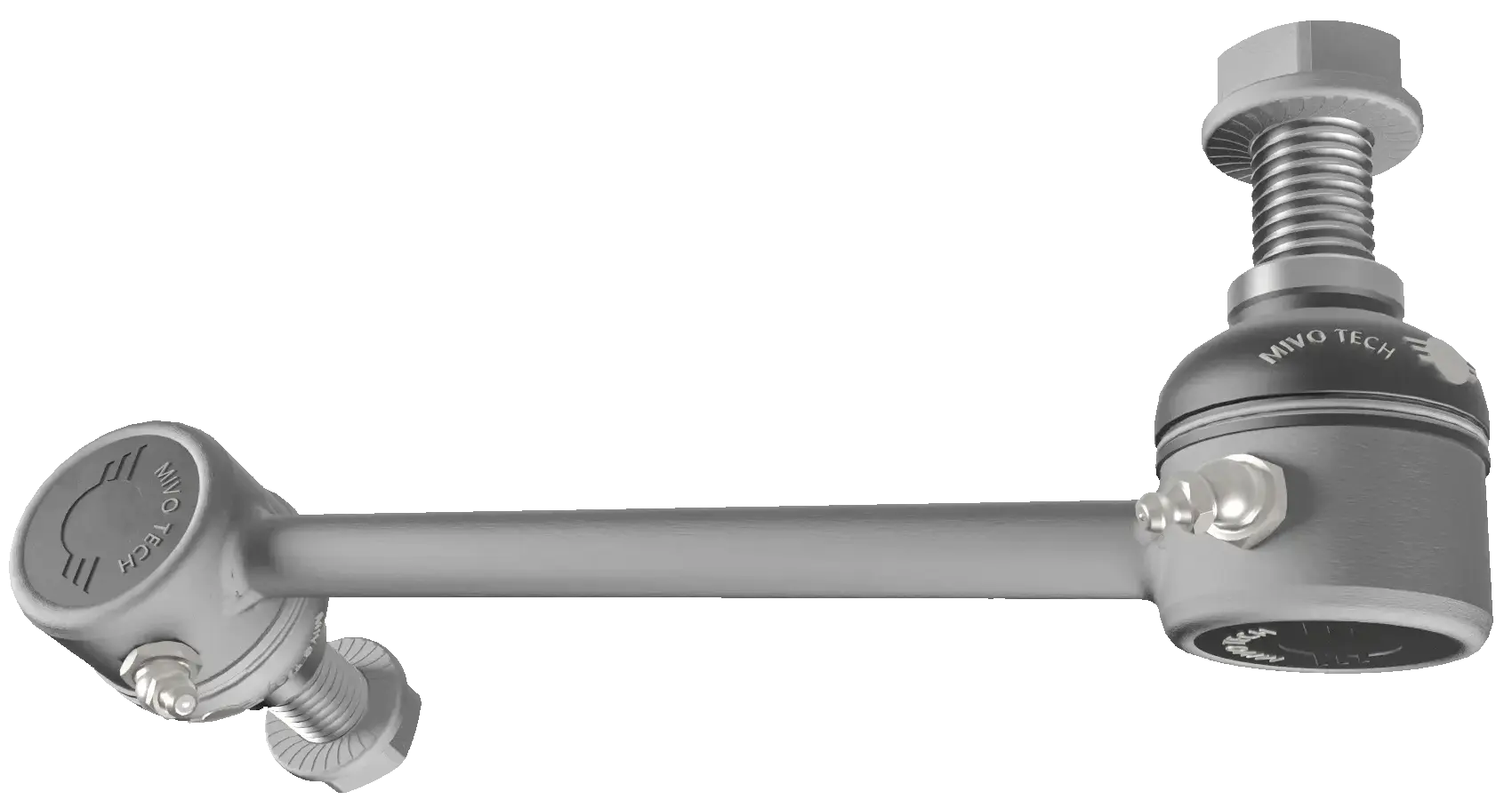

Stabilizer Links

Your ride will be safer and smoother thanks to our heavy-duty stabilizer links, which reduce body roll and increase cornering stability.

-

Control Arm Bushings

Our robust polyurethane control arm bushings, which are made to withstand tough environments, absorb shocks and preserve chassis stability.

-

Shock Absorbers

Our gas-charged monotube shock absorbers improve ride comfort and lessen body vibration, particularly on uneven or bumpy terrain.

-

Strut Mounts

Our precision-engineered suspension strut mounts cut noise, vibration, and harshness (NVH) while boosting performance under heavy-duty use.

Improving vehicle dependability and performance

High-quality suspension parts solutions

Suspension parts are essential components of a vehicle’s chassis system. They help absorb road impact, improve ride quality, and enhance handling and durability—especially important for heavy-use vehicles or off-road conditions. As a buyer, you will all face multiple challenges in quality, cost, customization, and supply chain when selecting suspension parts whether you’re an OEM manufacturer, an auto parts retailer, a purchasing manager, or a product designer.

However, we are here to help you learn about the various suspension part products, their respective application areas, and provide you with high-quality and competitively priced customized suspension parts.

Pain points concern you

MIVO faces all of your challenges directly

-

How to make sure the quality of suspension parts?

Suspension parts directly affect the safety and stability of the vehicle. If the quality is not qualified, it may lead to instability or safety hazards in the vehicle during driving. You need to ensure that the parts meet international standards and quality requirements.

-

How to control costs while ensuring quality?

You may already know that high-quality suspension parts are often more expensive, but if you can control the cost when purchasing, you can improve the market competitiveness of the product.

-

How to get truly custom suspension parts?

Every vehicle is different—whether it’s an off-road SUV, a light-duty pickup, or heavy-equipment machinery, you need parts built to your specs. That’s why we offer tailored suspension solutions, tweaking everything from arm geometry to bushing hardness and corrosion-resistant coatings so each component fits your application perfectly.

-

How can keep suspension parts supply chain stable?

Delays and shortages can mess up your whole production plan—especially when you’re dealing with essential parts like control arms or bushings. That’s why we keep buffer stock, offer lead times as short as 45 days, and provide reliable scheduling. With MIVO, you get a stable suspension parts supply chain you can count on—even when demand spikes.

-

Does the supplier have the ability to design and optimize suspension parts?

You need experienced engineers to provide you with technical services for product design and performance optimization. In some cases, engineers may need to modify your design.

-

How about after-sales service?

The quality of the product is the foundation, but after-sales service is equally important. You need to make sure that if something goes wrong with your product, you get timely technical support and problem resolution.

These are the most significant pain areas you experience. Nevertheless, we can help you overcome these obstacles and ensure that you get the best suspension components for your needs thanks to our vast expertise, which spans more than 15 years.

Our advantages

We provide supply chain solutions for you

As a suspension parts supplier with over 15 years of production experience, we can supply you with high-quality, customized suspension parts solutions due to our extensive industry knowledge, advanced manufacturing equipment, and strict quality control system.

Advanced production equipment and technology

How do we nail precision in every suspension part? With advanced kit like CNC machines, automated welding, and precision machining. This gear cuts out human error and guarantees consistent, accurate results – right down to the specs.

The strict quality management system

Our ISO 9001 & IATF 16949 certified factory runs strict quality control from raw materials to delivery.Every suspension component – like shock absorbers, control arms, sway bar links, bushings, and strut mounts – undergoes performance testing.Why? To guarantee your parts meet international standards, cut defects, and save you costly rework.

Customized service

Customized parts for your city and driving habits.Whether you’re dealing with extra body load, harsh climates, or off-road conditions, we build customized suspension components that match your specs. We build control arms to your specs and craft specialized bushings – each part precision-fit for its job.

Efficient lead time

Time is money, we get it. That’s why we’ve built our large-scale production and smart supply chain to deliver most custom suspension parts in just 45-60 days. Consider it our guarantee for getting you reliable parts, on time.

Competitive prices

You’ll get the best prices without compromising quality or performance because we offer factory-direct prices.

Perfect post-sales service

We provide a full range of after-sales support for each customer. Our team will provide professional technical guidance and consultation according to the use situation you offer and make sure that the product can deliver the best performance in actual use.

FAQ

Suspension components are what maintain a steady and comfortable ride. Key suspension parts names include sway bar links, bushings, control arms, shock absorbers, and strut mounts. Even on uneven terrain or at high speeds, they work together to absorb bumps and keep your wheels on the road.

Look for a supplier with proven quality standards (like ISO/TS certifications), stable delivery times, and the ability to handle custom needs. A factory-direct source like MIVO helps you cut costs without sacrificing performance.

What do ball joints in suspension parts mean?Ball joints are crucial parts that interconnect the wheels and control arms. They allow the suspension system to move freely while maintaining the handling and smoothness of the vehicle. View MIVO Ball Joints, which provide long-lasting, highly resistant custom ball joints. 👉 See MIVO Ball Joints

Most suspension parts have a range of 50,000 to 100,000 kilometers, depending on the driving conditions and component quality. The longevity may be increased by selecting high-quality parts, such our self-lubricating metal ball joints or stronger control arms.