Control Arm

OEM-Grade Suspension Arms for Global Vehicle Models

MIVO specializes in producing aftermarket control arms for cars, SUVs, and trucks. For American, German, Korean, and Japanese models, we provide long-lasting and reasonably priced solutions.

Fast lead times, custom materials, and packaging are available to meet your specific procurement requirements.

15+ years of production experience

Suspension control arm manufacturer in China

As a professional control arm manufacturer, we have excellent production capacity and strict quality control, always walking in the forefront of the industry. Our production facilities use internationally leading automated production lines to ensure product correctly and high quality, support small-batch customization for large-scale production, and are correctly to meet the needs of different customers. Fast delivery is our core advantage. Standard products can be delivered within 35 – 45 days, and customized products can also be flexibly arranged according to your needs to help you complete projects more efficiently.

In terms of quality control, we have received certification from worldwide automotive industry standards such as ISO/TS 16949, and our products have completed numerous rigorous tests for durability, corrosion resistance, and strength to assure dependable performance. We choose high-quality materials, such as steel, aluminum alloys, and composite materials, to provide the best solution in line with model requirements, and we use high-precision welding and anti-corrosion treatment technology to greatly improve product service life and become a trusted partner of customers in need of OEM suspension parts and aftermarket control arms.

Suspension control arm classification

-

Upper control arm

Positioned above the wheel hub, the upper control arm is mainly used in double-wishbone and multi-link suspension systems. It helps maintain camber angle and supports precise handling.

-

Lower control arm

Located beneath the suspension system, the lower control arm bears more load and is widely used in both front and rear suspensions for cars, SUVs, and light trucks.

-

Rear control arm

Installed in the rear suspension assembly, this control arm is essential for rear-wheel alignment and vehicle stability—especially common in independent multi-link systems.

-

Front control arm

Part of the front suspension, this component links the chassis and wheel hub, controlling vertical movement and improving ride comfort in modern cars and commercial vehicles.

-

Adjustable control arm

This type of control arm allows for alignment customization (camber/caster), making it ideal for off-road vehicles, modified suspensions, or racing applications.

-

Aluminum control arms

Made from lightweight aluminum alloy, these control arms are favored in high-performance cars and luxury vehicles, offering reduced unsprung mass and improved fuel efficiency.

-

Cast steel control arms

Engineered for durability, cast steel control arms provide high strength and rigidity, ideal for heavy-duty use in trucks, 4x4s, and utility vehicles operating in tough environments.

-

Stamped steel control arm

These stamped steel arms are dependable and reasonably priced, and their performance balance makes them popular in mass-market passenger cars.

-

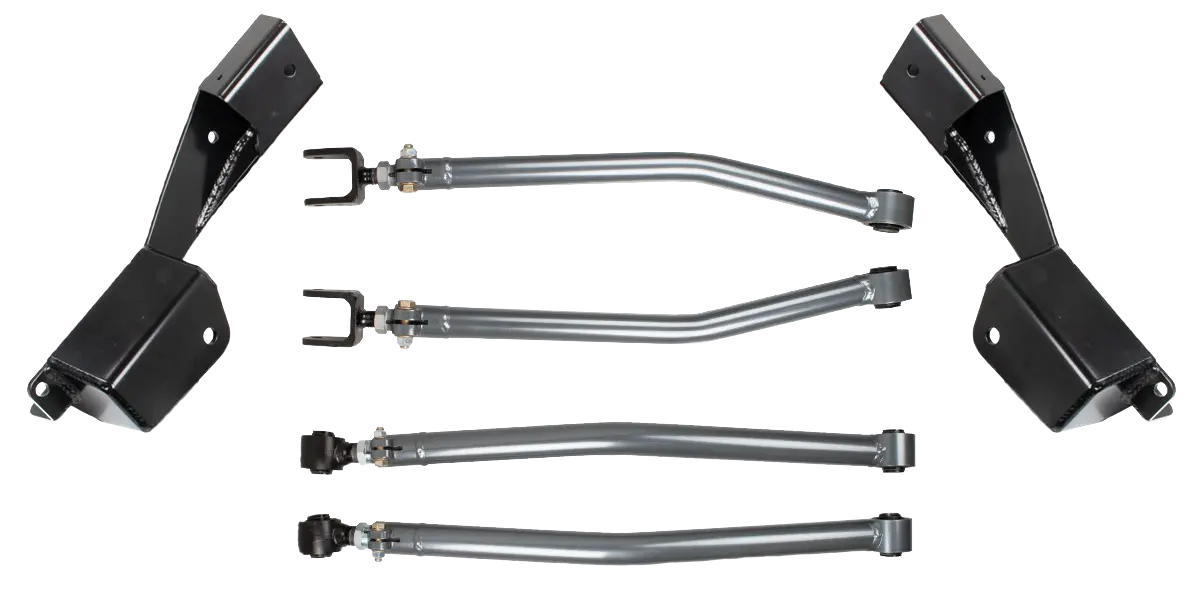

Upgrade control arms

These control arms are frequently utilized in off-road modifications, tuning, and racing since they are made for performance enhancements and have improved adjustability and strengthened materials.

Your decisions will be escorted

Control Arm Complete Guide: Definition, Uses, and Supplier Selection

The control arm is a core component of the automotive suspension system. It connects the chassis to the wheel hub, ensuring smooth motion, safe steering, and ride comfort. This complete guide will help you understand what a control arm is, its components, functions, and how to find a reliable OEM control arm supplier in China.

What do Control Arms do?

A suspension control arm plays multiple roles in a vehicle:

- Supports vertical wheel movement and maintains proper alignment angles.

- Transfers load between the wheels and vehicle body.

- Improves vehicle stability during braking, turning, and acceleration.

- Works with shocks and springs to absorb road impact and enhance ride comfort.

The main components of the control arm

A complete control arm usually consists of the following key components:

Control arm body

It is made of steel or aluminum alloy to provide strength and durability.

As the main structure, carrying the load between the wheel and the body.

Ball Joints

It is used to flexibly connect the suspension to the wheels, allowing them to rotate freely when steering.

It is usually made of high wear-resistant material to extend the service life.

-

Control Arm Bushings

Function: buffer vibration; reduce component wear.

Material: Rubber or polyurethane for flexibility and durability

-

Interconnecting piece

Including bolts, gaskets, etc., used to fix the control arm to the body or wheel to ensure firm and reliable.

How to find a reliable control arm manufacturer in China?

The following actions will help you locate a trustworthy control arm manufacturer in China and make sure you pick a good partner:

To select a trusted suspension control arm supplier, follow these 7 steps:

- Define Requirements: Load specs, vehicle compatibility, materials (steel/aluminum), certifications (ISO 9001, IATF 16949).

- Contact Directly: Ask for factory qualifications, product samples, and production capabilities.

- Factory Visit: Evaluate production lines, equipment, and quality control systems.

- Third-party Audit: Use SGS, TUV, or agents for factory verification if travel is not feasible.

- Small Batch Trial: Test production speed, communication, and quality before mass orders.

- Check Industry Clusters: Focus on regions like Zhejiang, Jiangsu, and Guangdong for auto parts manufacturers.

- Contract + NDA: Sign clear purchase contracts and protect IP with NDAs.

By following these steps, you can improve your chances of finding a reliable control arm manufacturer while reducing your risk. Or contact us directly.

Avoid the Pitfall of Choosing Low-Price Suppliers

Going with the cheapest quote may result in:

- Use of low-grade materials and poor process control.

- Unexpected costs in rework, maintenance, or delayed delivery.

- Inadequate quality control or absence of post-sale support.

- Compliance and IP risks, especially in export-oriented contracts.

Choose long-term value over short-term savings—especially for key automotive suspension components.

MIVO’s Control Arm Supply Process

- Requirement Collection: Send inquiries or upload drawings via website or sales team.

- Sample Production: We provide prototype batches for testing and validation.

- Mass Production: Production is scheduled upon sample approval.

- Global Logistics: MIVO offers export-ready packaging and fast shipping worldwide.

- After-sales Support: Our engineers are available for technical assistance and feedback follow-up.

FAQ

While offering specialization to address particular demands, we also provide standardized items that cover popular models.

While aluminum alloy is more suited for high-end, lightweight requirements, steel is better suited for the quest of durable and cost-effective clients.

We offer complete process modification services, including production, packaging, and brand identification, starting with design optimization and ending with material selection.

Look for symptoms like uneven tire wear, steering wheel vibration, or clunking noises over bumps. A visual inspection may show damaged bushings or ball joints.

It’s often recommended to replace control arms in pairs (left/right) for even suspension performance, especially if the other one shows signs of wear.

OE control arms match the original factory specs, while aftermarket arms may offer performance upgrades or improved materials at lower cost.

Listen to our clients how to saying about us

You will quickly understand our capabilities from our clients’ reviews.

Our company cooperated with the technical department of MIVO to deal with the technical difficulties of the project. They were very professional and could propose different solutions for us to choose from.

MIVO understands our needs better and has a detailed response to our needs. This is the most important in the procurement process and their after-sales service is also responsive.

I often visit the MIVO manufacturer, they will assist me to deal with all the visa issues, and will meet us at the airport. They understand the customs of different religions and all the services are very professional.