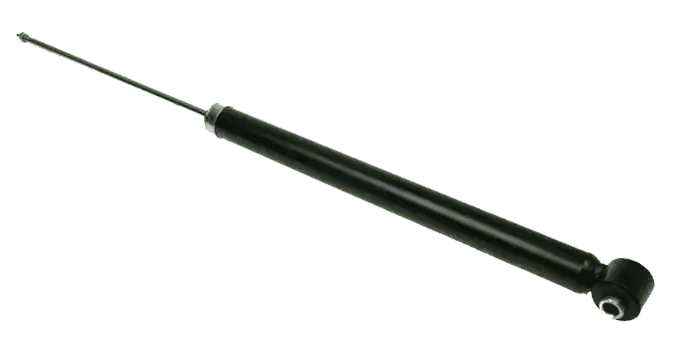

Rear shock absorber

✅ Military quality Rear Shock Absorber manufacturer

✅ Commercial fleet suspension system transformation solution provider

The MIVO factory provides you with the ultimate Rear shock absorber guide

Reply within 2-8 hours

Via E-mail

MIVO sales and technical teams provide service 24/7

- Decoding industry status quo — cost black hole caused by Rear Shock Absorber failure

- Technological revolution-five innovation dimensions of Rear Shock Absorber in MIVO factory

- Manufacturing strength — Precise intelligent manufacturing system of digital factory

- Business value – TCO full cycle cost optimization model

- Service network — 200+ technical service stations to build a carefree ecology

- Authoritative certification — the quality endorsement of the world’s top institutions

Chapter 1: Decoding industry status quo — cost black hole caused by Rear Shock Absorber failure

1.1 The harsh reality revealed by big data

Economic loss from failure: Data from China Logistics Association show that the annual average loss due to rear shock absorber failure in 2023 is:

▶ Maintenance cost: USD 8,400/ vehicle

▶ Cargo loss: USD 15,200/ car

▶ Insurance premium: USD 3,750/ car

Security risk alarm:

The report of the National Vehicle Quality Inspection Center states:

✅ 65% of suspension accidents result from rear shock absorber metal fatigue

✅ 82% of abnormal braking distance is directly related to the failure of shock absorber fluid

1.2 Technical dilemma of traditional products

Material defects: the corrosion rate of ordinary carbon steel in humid environment reaches 0.12mm/ month

Design injury:

▶ Single cylinder structure leads to low heat dissipation efficiency

▶ Linear damping cannot adapt to multi-terrain conditions

Adapt to chaos:

▶ European standard/American standard/national standard parameters are mixed

▶ Non-standard custom delivery cycle over 45 days

Chapter 2: Technological revolution-five innovation dimensions of Rear Shock Absorber in MIVO factory

2.1 Material innovation: aerospace grade alloy forging

Composite cylinder block technology:

▶ Outer layer: TC21 titanium alloy (tensile strength ≥1100MPa)

▶ Interlayer: silicon nitride ceramic coating (Mohs hardness 9.2)

▶ Core: Shape memory alloy (deformation recovery rate 99.7%)

Intelligent damping medium:

✔ NanoGel™ temperature controlled fluid: -50 ° C still maintains fluidity

✔ Magnetorheological fluids: millisecond level damping adjustment response

2.2 Structural innovation: bionics design breakthrough

Honeycomb matrix buffer system:

▶ Hexagonal elements decompose the impact force

▶ 3D pressure relief channel design

Dual-mode working system:

▶ Highway mode: energy saving and noise reduction

▶ Off-road mode: Peak capacity +35%

Chapter 3: Manufacturing strength — Precise intelligent manufacturing system of digital factory

3.1 Industry 4.0 Production matrix

Process intelligent equipment precision control

| Hot forming | Switzerland ABB robot arm + Germany TRUMPF laser cutting | ±0.02mm |

| Welding | Japan FANUC robot + visual positioning system | weld strength ≥ base metal |

| Final assembly | automatic tightening machine +AI quality inspection instrument | torque error ≤0.5% |

3.2 Quality assurance pyramid

Basic layer: spectral detection of raw materials (sampling rate of each batch is 100%)

Core layer:

▶ 24 process traceability system

▶ 72-hour salt spray test (ASTM B117 standard)

Tip layer:

▶ Data collection of 200,000 km road test of real vehicles

▶ Certification of Tribology Laboratory of Tsinghua University

Chapter 4: Business value – TCO full cycle cost optimization model

4.1 Empirical study on Cost comparison (H2)

Transformation case of 30 heavy trucks in a logistics enterprise

| Indicator | Before transformation(normal parts) | After transformation(MIVO Parts) | Optimization rate |

| Annual failure times | 3.2 times | 0.4 times | 87.5% |

| Single repair time | 8.5 hours | 1.2 hours | 85.9% |

| Tire wear rate | Benchmark value | -18% | —— |

4.2 Map of implicit Returns (H2)

Safety value: 72% reduction in roll risk (CNCAP test data)

Management value:

▶ Maintenance personnel hours saved by 65%

▶ 40% reduction in spare parts inventory

Environmental value:

▶ 1.2 tons of CO₂ emission reduction per vehicle per year

▶ 100% recyclable

Chapter 5: Service network — 200+ technical service stations to build a carefree ecology

5.1 Three-level response system

Basic services:

✅ 7×24 hours online selection guidance

✅ Electronic installation manual real-time download

Value-added services:

▶ Free on-site training for key customers

▶ AR Augmented reality maintenance guide

Emergency Services:

▶ Dispatch of urgent items within 2 hours from provincial warehouse

▶ Special plane distribution channel for strategic customers

5.2 Digital Service Tools

Intelligent diagnosis platform:

▶ Scan code to read running data

▶ AI algorithm predicts the remaining life

Cloud configurator:

▶ Enter the three parameters of wheelbase/load/road condition

▶ Automatically generate 3D model drawings

Chapter 6: Authoritative certification — the quality endorsement of the world’s top institutions

6.1 Authentication Matrix

Safety certification:

✅ ECE R90 (EU)

✅ FMVSS 571.105 (US)

Environmental certification:

▶ RoHS 2.0

▶ REACH SVHC

Industry Certification:

▶ IATF 16949:2016

▶ ISO 45001:2018

6.2 Benchmarking customer cases

Deppon Express National Fleet upgrade Project

Modified vehicles: 8,200 units

Quantitative returns:

▶ saves ¥36.8 million in annual maintenance costs

▶ Reduced the loss rate by 2.3 percentage points

▶ An 81% reduction in complaints of lower back problems among drivers

FAQ:

Immediate repair is recommended when 3 or more of the following symptoms occur:

✔ Abnormal metal crashing sound on continuous bumpy roads (72% probability)

✔ Measuring wheel arch height difference > 15mm under no-load condition

✔ Increased tail swing by over 40% when braking

✔ More than 1.2mm tire wear per 10,000 km

We have achieved five breakthroughs with military-grade technology:

Material innovation: TC21 titanium alloy cylinder block has 320% higher fatigue strength than ordinary carbon steel

Intelligent response: Magneto-rheological fluid can achieve 0.008 seconds damping adjustment response

Extreme working conditions: -50℃~200℃ environmental performance fluctuation < ±5%

Environmental protection certification: through RoHS 2.0+REACH double standards

Service guarantee: provide 120,000 km /24 months of ultra-long warranty

Industry 4.0 flexible production line to achieve graded delivery:

Customization level delivery cycle Typical application scenario

Standard variant 5-7 days wheelbase fine-tuning/load adaptation

Deep customization of special vehicles/new energy models for 12-15 days

Extreme environment version 20-25 days polar research vehicle/mining equipment

We have built a triple protection system:

Substrate protection: laser cladding of 0.2mm chromium nitride coating on the cylinder surface (salt spray test > 1000h)

Structure protection: patented labyrinth sealing structure (dust-proof and waterproof grade IP68)

Chemical protection: special anti-corrosion coating set (PH 1-13)

Three innovation modules are developed for the trend of electrification:

▸ Energy recovery type: 30% vibration kinetic energy can be converted into vehicle electricity

▸ Lightweight version: carbon fiber composite material to reduce weight by 47%

▸ Intelligent diagnostic interface: CAN bus data transmission (compatible with Tesla Semi, BYD Q3 and other mainstream models)

We provide three verification methods:

Laboratory report: Check the 720,000 fatigue test report issued by the Tribology Laboratory of Tsinghua University

Customer witness: Retrieved the actual usage data of Deppon logistics fleet of 320,000 kilometers

On-site measurement: Make an appointment to visit the ongoing 24-hour ultimate impact test (peak load 8 tons)

We have built a four-level technical service system:

Intelligent pre-diagnosis: scan code to obtain AI-generated maintenance suggestions (accuracy 92%)

Video guidance: Cloud reserve 200+ HD installation and debugging tutorials

On-site service: 4-hour emergency response at provincial level (including delivery of special kits)

In-depth training: two free engineer certification courses per year

Refer to our load-model matching matrix:

Vehicle load recommended series damping coefficient range

3-8 tons EconoDamp™ 1800-2500N·s/m

8-15 tons ProShock® 2800-4000N·s/m

15-30 tons MegaRide™ 4500-6000N·s/m

Full compliance worry-free:

✔ Provide E-mark certification documents (ECE R90 standard)

✔ Standard line – free installation solution

✔ Cooperative insurance companies to underwrite product liability insurance (a single accident maximum compensation of 5 million)

We implement intelligent pricing model:

▸ Basic quantity: ≥50 sets enjoy 10% discount + free logistics

▸ Strategic procurement: 15% discount + exclusive coding system for ≥200 sets

▸ Annual agreement: 20% discount on committed purchase volume + free inventory management

Listen to our clients how to saying about us

You will quickly understand our capabilities from our clients’ reviews.

Our dump trucks carry 15-ton loads on mountain roads. MIVO’s rear shocks lasted 28,000km – 35% longer than previous brands. The rebuild kits come with laser-etched torque specs on the housings.

“MIVO pre-tests shocks for our refrigerated trailers’ vibration profiles. Their field engineer spent two days measuring our typical 65-75km/h highway rhythms.

I communicated with them online and discussed the requirements. They completed the production very quickly and shipped it to me. Their products are very good.