Structure & Components: Inner, Outer, End, Assembly

Tie Rod Assembly

- Inner Tie Rod: Bolts directly to the steering rack. It’s usually hidden behind the engine cradle and connects to the outer tie rod via a threaded sleeve.

- Adjustable Sleeve: A knurled or hex‑shaped spacer that allows alignment adjustment (toe‑in/out).

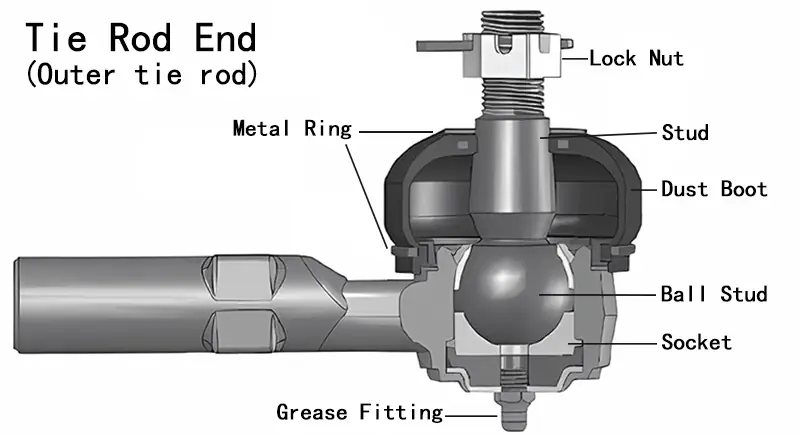

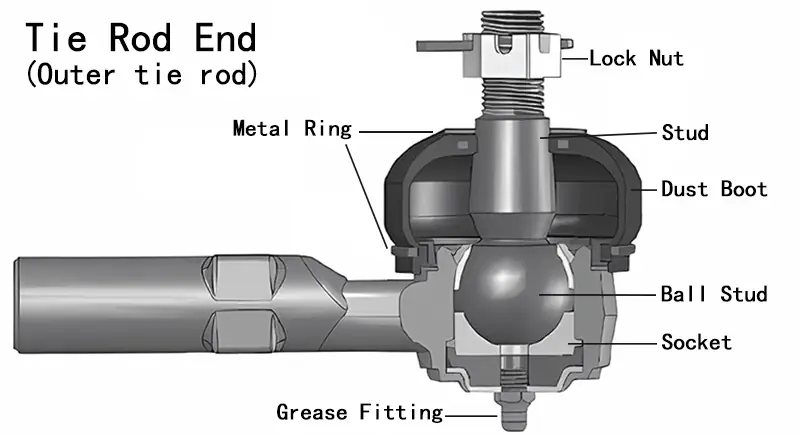

- Outer Tie Rod End: Screws into the sleeve and mounts to the steering knuckle. It contains a ball‑and‑socket joint to allow angle changes.

Ball Joint Components

- Ball Stud: The hardened, spherical pivot that fits into the socket.

- Socket (Cup): Houses the ball stud and provides the bearing surface.

- Bearing Surface: Often lined or coated to reduce friction.

- Protective Boot: A rubber “dust boot” that seals in grease and keeps out dirt. Some designs include a grease fitting (zerk) for maintenance.

Functions Compared: What Do They Do?

| Function Category | Ball Joint | Tie Rod |

|---|

| System | Suspension | Steering |

| Motion Allowed | Vertical + lateral rotation | Primarily lateral rotation |

| Primary Task | Pivot and support wheel movement | Transmit steering input to wheels |

| Adjustment Capability | None | Toe‑in/toe‑out via adjustable sleeve |

| Load Bearing | Yes (upper & lower share load) | No (connects steering parts) |

| Common Symptoms of Wear | Clunking, vibration, uneven tire wear | Loose steering, tire scalloping, knocking on turns |

Key Differences Between Ball Joints and Tie Rods

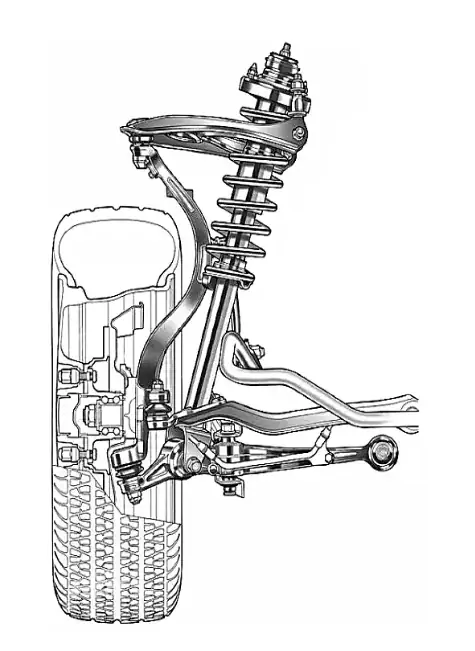

While both ball joints and tie rods are critical components in a car’s suspension and steering system, their structure, location, and function differ significantly.

| Component | Function | Location | Key Role |

|---|

| Ball Joint | Connects control arm to steering knuckle, allows multi-directional movement | Front suspension (upper and lower control arms) | Pivot point for wheel movement and suspension articulation |

| Tie Rod | Transfers motion from steering rack to steering knuckle | Steering system (inner and outer tie rod ends) | Controls the direction of the front wheels when steering |

Symptoms of Bad Ball Joints vs Tie Rods

Both failing tie rods and ball joints can cause steering problems, noise, and irregular tire wear, but their symptoms vary slightly.

Bad Ball Joint Symptoms

- Clunking noise when driving over bumps

- Uneven tire wear

- Loose or wandering steering

- Excessive vibration in the steering wheel

Bad Tie Rod Signs

- Loose steering or excessive play in the wheel

- Uneven or scalloped tire wear

- Knocking or popping sounds during turns

- Car pulling to one side

Want to learn more? Visit our Symptoms of Bad Ball Joints page for detailed diagnosis.

Inspection & Maintenance Tips

Understanding how to check ball joints and tie rods is essential for preventative maintenance.

🛠 How to Check Ball Joints:

- Lift the vehicle and try moving the tire vertically (12 and 6 o’clock positions).

- Look for excessive play or clunking noise.

- Visually inspect the dust boot for cracks and grease leakage.

🛠 How to Check Tie Rods:

- Move the tire horizontally (3 and 9 o’clock positions).

- Observe for play in the inner or outer tie rod ends.

- Look for loose tie rod connectors and worn bushings.

Maintenance Notes:

Tie rods and ball joints should be inspected every 10,000–15,000 miles.

Replace inner and outer tie rods or tie rod assembly if worn beyond spec.

Conclusion & Replacement Advice

When to Replace Tie Rods and Ball Joints ?

Whether you’re dealing with tie rod end symptoms like loose steering, or ball joint issues and repairs such as clunking noises and uneven tire wear, knowing the difference between these two parts is crucial for safe driving.

If you’re asking yourself, “How to check ball joints and tie rods?”—the answer is simple: listen, feel, and inspect. When in doubt, schedule a professional diagnosis. Ignoring early signs can lead to dangerous driving conditions or more expensive suspension damage down the line.